Product Approval Process

Product Approval Process is a valuable tool for establishing confidence between customers and the suppliers. In today’s competitive manufacturing environment, while suppliers are wooing customers with lower prices without the promise of product quality, we go one step further to strengthen the bond with our customers. Many component parts are being outsourced to overseas manufacturers. This often results in longer lead times and larger order quantities. Therefore, it has become imperative to provide quality parts that meet the customer’s requirements the first time and every time.

The customer may request a limited number of product approval at any time during the product life.

1. Design documentation shall include both a copy of the customer and our drawings. The documentation should also include a copy of the purchase order.

- The purchase order is used to confirm that the correct part is being ordered and that it is at the correct revision level.

- The design engineer is responsible for verifying that the two drawings match and all critical or key characteristics have been identified.

- Material composition information is required to supply evidence that the material used manufacture the parts meets the customer’s specific requirements.

2. Process Flow Diagram

The Process Flow Diagram outlines the entire process for assembling the component or final assembly in a graphical manner. The process flow includes incoming material, assembly, test, rework and shipping.

3. Control Plan

The Control Plan lists all product Special Characteristics and inspection methods required to deliver products that continually meet the customer quality requirements.

4. Recordings

- Measurement System Analysis (MSA) studies will include Gage Repeatability & Reproducibility (GR&R) studies on measurement equipment used during assembly or quality control checks.

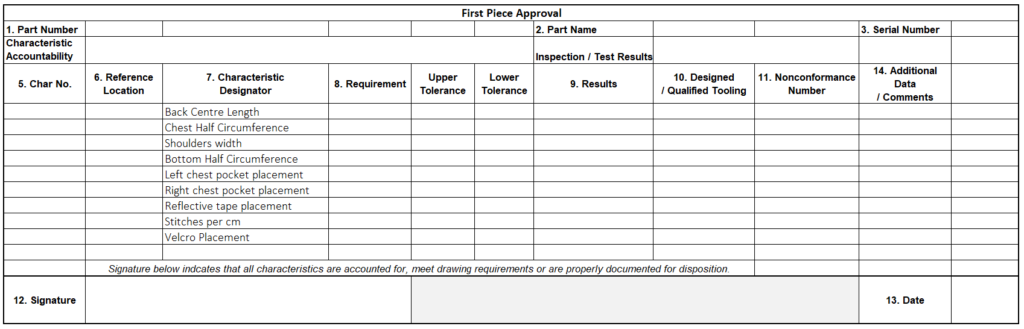

Calibration records for all gages and measurement equipment must be included. - Dimensional layout of sample parts is required to validate the product meets the print specifications. The samples should be randomly selected from a significant production run usually at least 10 pieces. Each dimension on the drawing is measured on the final assembly to make sure that it falls within specification. The results are recorded in a spreadsheet.

- Qualified laboratory documentation consists of the industry certifications for any lab that was involved in completing validation testing. This could be for an in-house test lab or any offsite contracted test facilities that were used for validation or material certification testing.

- The Appearance Approval is applicable for components affecting appearance only. This report verifies that the customer has inspected the final product and it meets all the required appearance specifications for the design. The appearance requirements could include information regarding the color, textures, etc.

- A master sample is a final sample of the product that is inspected and signed off by the customer. The master sample part is used to train operators and serves as a benchmark for comparison to standard production parts if any part quality questions arise.