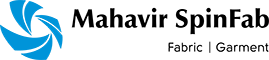

Electricity is an essential part of our lives, but it can also be hazardous. In power generation companies, workers are often exposed to high voltage electricity and electrical equipment, which can create the risk of an arc flash. An arc flash is an electrical explosion that can release tremendous amounts of thermal energy, resulting in severe burns, blindness, and even death. To protect workers from the dangers of an arc flash, electric arc flash suits are used.

The primary purpose of an electric arc flash suit is to protect workers from the thermal energy released by an arc flash. These suits are made from flame-resistant fabrics that can withstand high temperatures, minimising the risk of injury or death. The suits cover the entire body, including the head, face, and hands, and are designed to provide a barrier between the worker and the electrical energy.

There are several fabrics that can be used to make electric arc flash suits, each with its own unique properties. Some of the most commonly used fabrics at Mahavir include:

- Nomadic Aramid Pyo: Aramid Pyo deploys the use of Pyrotek, a specially engineered fiber that provides enhanced protection from electric arcs as well as anti-odour properties.

- Nomadic Pro Aramid: The composition of Modacrylic, Cotton, Para-Aramid and Carbon makes it an economical solution to combat varying degrees of electric arc hazards.

- Nomadic Aramid Prime: This is a blend of meta-aramid, para-aramid and anti-static that is used in a variety of protective clothing, including electric arc flash suits. The fabric is heat resistant and can withstand temperatures up to 400 degrees Celsius. It is also lightweight, comfortable, and has excellent tear and abrasion resistance.

All these fabrics come in various weights and weaves offering different levels of protection from HRC1 to HRC4 categories. Contact us at info@msfgroup.in to learn more about which fabric suits your use case.

Besides the fabric used to make electric arc flash suits, it is also important to consider other factors such as the fit of the suit, the level of protection required, and the specific hazards of the job. Employers should provide their workers with appropriate training on how to use and maintain their electric arc flash suits, as well as other personal protective equipment that may be required.

In conclusion, electric arc flash suits play a crucial role in protecting workers in power generation companies from the dangers of an arc flash. Different fabrics can be used to make these suits, each with their own unique properties and advantages. It is important for employers to provide their workers with the appropriate personal protective equipment and training to ensure their safety in high-risk work environments.