India's First Recycled IFR Garments launched by Mahavir SpinFab

Mahavir SpinFab has set a new benchmark by launching India’s first recycled Inherent Flame-Retardant (IFR) garment—a major leap toward circular safety in the protective textile industry. For the first time, end-of-life IFR garments are being transformed into new, high-performance protective wear, proving that safety and sustainability can go hand in hand.

This innovation is rooted in textile recycling, where used IFR garments are recovered and re-engineered to extend their lifecycle. By doing so, Mahavir SpinFab reduces textile waste, lowers carbon emissions, and conserves natural resources—making protective clothing smarter and cleaner.

Traditionally, protective wear focused only on keeping workers safe. Now, it also protects the planet. Mahavir SpinFab’s recycled IFR garments are setting new standards for industries like oil, gas, petrochemicals, and construction—where sustainable textile solutions are urgently needed.

This is the future of protective clothing: safe, sustainable, and circular. Mahavir SpinFab invites you to join the movement. Let’s build a world where safety gear not only saves lives—but also supports a healthier planet.

Have you ever wondered where protective clothing goes after its job is done?

Every day, Millions of IFR garments protect lives in Oil, Gas, and Petrochemical industries. But once their job is done, These IFR garments are discarded after use, often ending up in landfills or incinerators. Incineration releases toxic gases, while landfilling leads to long-term accumulation and pollution.

Challenges of IFR Waste on Health and Environment

Improper disposal of IFR waste leads to long-lasting pollution. These non-biodegradable materials stay in landfills for years, harming ecosystems and adding pressure to already strained waste systems.

Landfilling

Incineration Hazards

Resource Wastage

Carbon Footprint

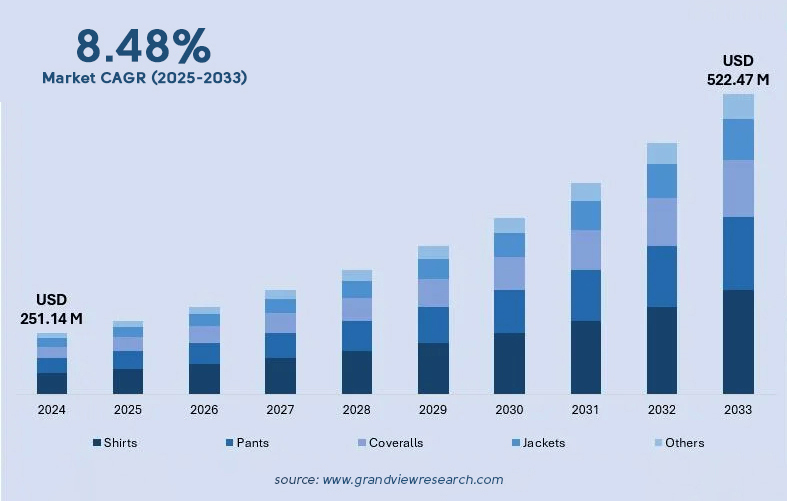

Global IFR Apparel Market on the Rise

The global Inherently Flame Retardant (IFR) clothing market is projected to grow from USD 251.14 million in 2025 to USD 522.47 million by 2033, at a CAGR of 8.48%. This growth is driven by rising safety demands across industrial sectors. But increased production of IFR fiber-based garments—often treated with complex chemistries—raises sustainability concerns. The industry must shift toward closed-loop recycling, non-toxic FR technologies, and durable, recyclable IFR fabrics to align with climate goals and reduce environmental impact.

Circular Solutions for a Safer World

At Mahavir Spinfab, we believe that true safety extends beyond protection it includes protecting the planet. Our Recycling & Circularity Program is designed to give IFR garments a second life, reduce waste, and support a sustainable future for technical textiles.

The Journey of Transformation

Every used IFR garment carries a story of protection. Instead of letting it end as waste, we begin a new journey—one of renewal and responsibility. Through our advanced recycling process, these garments are carefully collected, shredded into fibers, spun into fresh yarn, and woven back into high-performance Garments

1. Collection

Used IFR garments from oil and gas industries are gathered and sent to specialized recycling centers, initiating a sustainable loop that prevents landfill waste and promotes responsible material recovery.

2. Sorting

Garments are sorted by fiber type, color, and condition to ensure consistent input quality. This step is crucial for maintaining performance standards in the recycled output.

3. Decontamination

Industrial washing removes oils, chemicals, and contaminants. Non-textile components like zippers and reflective tapes are extracted, leaving clean textile material ready for safe, high-quality recycling.

4. Shredding

Clean garments are mechanically shredded into small pieces, then processed into fibrous material. This transformation enables further blending and reuse in new textile applications.

5. Fibre Mixing

Recycled fibres are blended with virgin fibres based on performance needs. This enhances strength, uniformity, and ensures the final yarn meets industrial safety and durability standards.

6. Spinning

Prepared fibres are spun into yarn using industrial spinning systems. This yarn becomes the foundation for weaving IFR fabric, continuing the circular textile journey.

7. Weaving

Spun yarn is woven or knitted into IFR fabric using advanced looms. The resulting fabric retains flame-resistant properties and meets stringent safety specifications.

8. Garmenting

IFR fabric is cut, stitched, and finished into protective garments like coveralls or jackets. These are ready for reuse in hazardous industrial environments, completing the circular loop.

Key Pillars of Our Program

Collaboration and strong partnerships further strengthen our reach, while our commitment to quality and excellence ensures high standards in every step. Finally, we believe in continuous learning and growth, adapting to change and preparing for the future with resilience.

Sustainability

Circularity

Innovation

Collaboration

Responsibility

Certifications

Ensuring compliance with GRS, EN ISO 14001:2015 and OEKO-TEX.

Awards and Recognition

From innovation to impact, these awards and recognition reflect our dedication to a sustainable future.

Awarded 3rd Most Innovative Product at OSH 2025, this milestone reflects our unwavering commitment to pioneering solutions that extend garment life, minimize textile waste, and reduce carbon emissions, all without ever compromising safety or performance.

We proudly introduced India’s FIRST recycled IFR garment, a groundbreaking innovation that is redefining the future of sustainable protective clothing. This isn’t just a garment – it’s a bold step toward a circular economy in industrial safety, where every piece of clothing works twice as hard for people and the planet.

The future of protective clothing is sustainable, resilient, and here – and Mahavir SpinFab is leading the way.

Safety & Sustainability Stories

Explore our research stories, where innovation in recycling is shaping the future of protective clothing. By rethinking the lifecycle of IFR garments, we are creating sustainable, high-performance solutions that redefine industry standards. Through insights, breakthroughs, and real stories, we share our journey of transformation—proving that safety and sustainability can go hand in hand.

Let’s Recycle Together

Have questions about our recycled IFR garments? Send us a message—we’ll get back quickly.

Special Recycling Programme for IOCL Employees

Contact Us

Whether by phone, email, or a visit—our team is always ready to assist you.

Call Us

Email Us

Office Location

FAQs

Answers to the most common questions about our recycling solutions.

Our IFR garments are made using a closed-loop recycling process that transforms end-of-life protective clothing into new, flame-retardant apparel. This innovation reduces textile waste and preserves critical safety properties.

Yes. Every recycled garment undergoes rigorous testing to ensure it meets or exceeds industry standards for flame resistance, durability, and protective performance—matching the safety of virgin IFR fabrics.

We partner with industries to collect worn-out IFR garments, sort and process them using advanced mechanical recycling, and re-engineer the fibers into new protective textiles—without compromising safety or quality.

Incinerating or landfilling IFR garments releases toxic gases and contributes to environmental degradation. Our recycling process prevents harmful emissions, conserves resources, and supports a circular economy.

Circular safety means designing protective clothing that can be safely recycled and reused—reducing environmental impact while maintaining life-saving performance. Mahavir SpinFab is India’s first to achieve this for IFR garments.

Industries such as oil & gas, electrical utilities, metallurgy, and firefighting benefit from our sustainable IFR solutions—meeting both safety regulations and sustainability goals.

By reducing waste, lowering carbon emissions, and promoting circularity, our recycled IFR garments help companies meet Environmental, Social, and Governance (ESG) targets while enhancing brand responsibility.

Yes. We are proud to be India’s pioneer in launching recycled IFR protective wear—setting new benchmarks for sustainability and safety in the textile industry.

Yes. We offer customization options including logos, colors, and garment styles—ensuring your team stays protected while representing your brand sustainably.